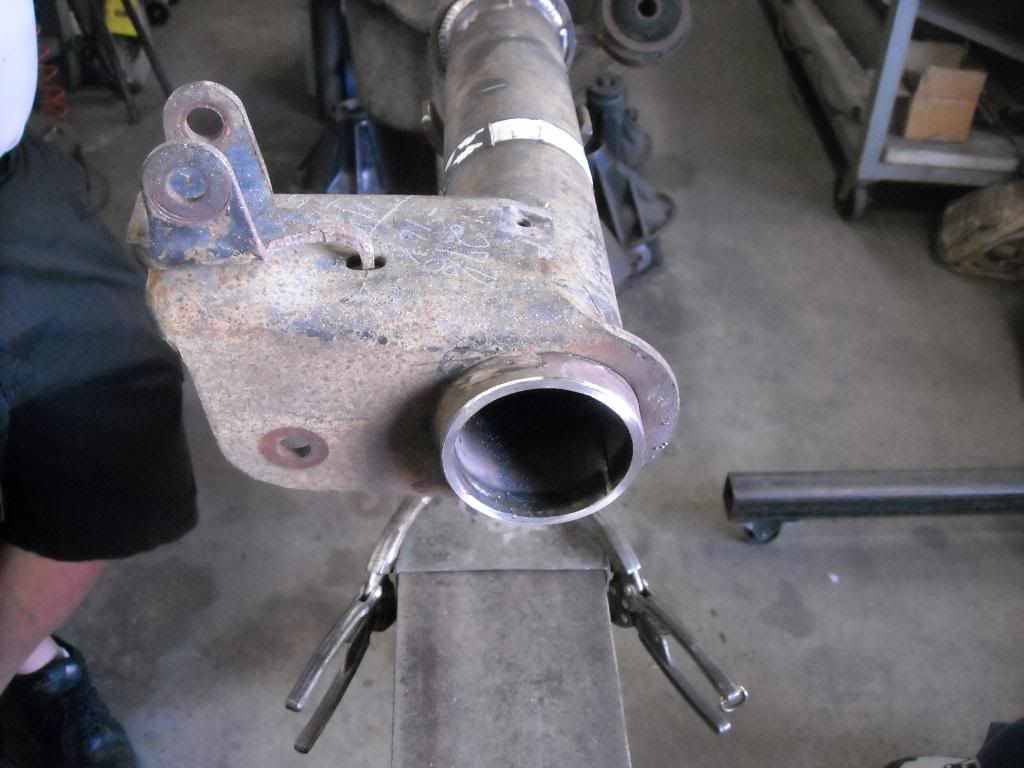

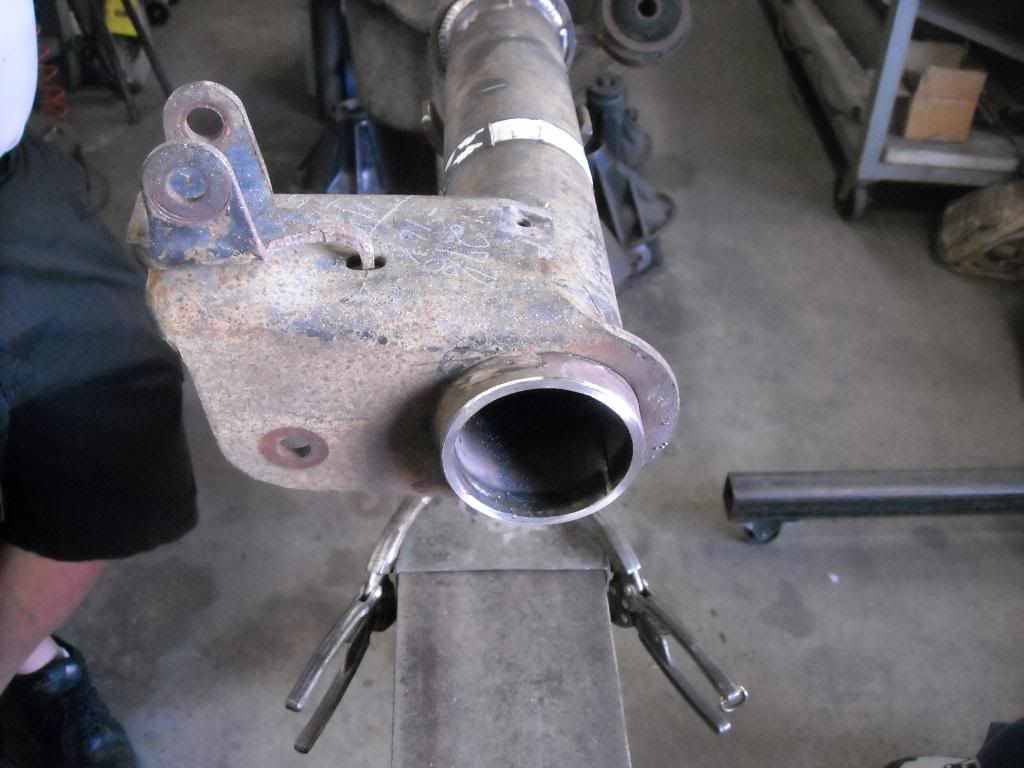

Well my new WMD Project car is underway and I started by building the rearend. I took it to Bob Meyer Race Cars in El Cajon. Bob has been building race cars since the early 70's, so he knows a thing or to about engineering. He basically designed a truss after the golden gate bridge. I wanted to post this here to show you guys the kind of work he does. Anyone thinking of getting tubes welded to the center section, he is the man to go to.

This 8.8 has been shortened 2" on each side, had axle tubes welded to the center section, coil over brackets welded on, 9" housing ends welded up and a 5pt chrome moly truss making this axle just about as rigid as you can get. This bad boy ain't bending.

Here are some pics of the 8.8

This 8.8 has been shortened 2" on each side, had axle tubes welded to the center section, coil over brackets welded on, 9" housing ends welded up and a 5pt chrome moly truss making this axle just about as rigid as you can get. This bad boy ain't bending.

Here are some pics of the 8.8

lol

lol